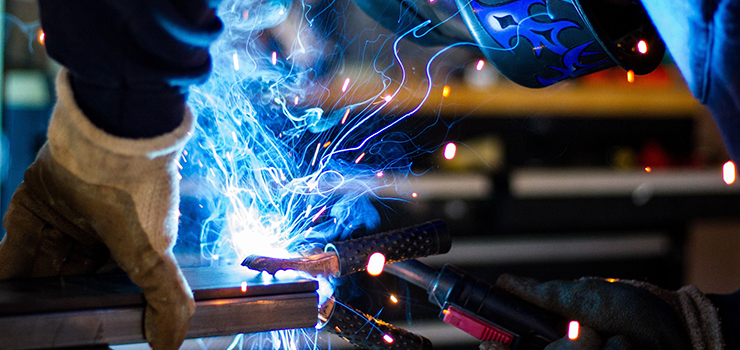

Welding

MANUAL AND AUTOMATIC WELDING

Tried, tested and extremely reliable

Since the company was set up in 1966, welding has been one of BRUDER-KELLER’s core competencies, including all established welding procedures such as: - MAG WELDING (Metal Active Gas welding) - MIG WELDING (Metal Inert Gas welding) - WIG WELDING (Wolfram Inert Gas welding), also known as TIG WELDING (Tungsten Inert Gas welding) - COLD ARC WELDING - SPOT WELDING. Our numerous welding sources are permanently in use: 22 MIG/MAG welding units, 8 TIG units, 11 spot welding machines and welding guns with a performance rating of 25 to 335 kVa (also usable for aluminum). All our equipment comes from leading manufacturers (ARO, SCIAKY, EWM, FRONIUS). Two 8-axis MOTOMAN WELDING ROBOTS connected to a rotary tilting table are also in use three shifts a day. Furthermore, they can quickly be reset from MAG to MIG or WIG as necessary. Bruder-Keller aims to be one of the industry’s technological pioneers, as it was when it purchased its first robot system from MESSER-GRIESHEIM in 1981. Since then the fourth generation of robots has already moved into our welding department, and, of course, we have our own in-house tool shop, enabling us to customize our welding templates and supports to meet your needs. The welding technology we use also complies with the strict requirements of ISO 3834-2. The official German technical inspection association TÜV regularly supervises this quality management system. Two highly qualified welding engineers guarantee the highest quality standards and work closely with our welding specialists. We use the ideal welding procedure for each application. Our experienced welders have been trained and have received certification in all established procedures. They also hold licenses from TÜV and the French equivalent APAVE. The quality of their work surpasses standard quality requirements (such as Euronorm and ASME standards). Our ISO 3834-2 certification reflects the quality of their work. If required, all our welding seams can be checked by means of (amongst other methods): - Tensile tests - Dye penetration tests - Magnetic particle testing - Ultrasonic testing - Radiographic testing - Determination of delta-ferrite content - Water pressure tests. Our commitment to the highest level of quality assurance is an absolute priority and explains why Bruder-Keller has been an authorized contractor for the nuclear power industry since 1978. There is good reason why our customers have confidence in our uncompromising reliability!